Best Bottled Water Packaging Line: ZONESUN ZS-FAL32-10

ZONESUN Technology Limited, a leader in automatic packaging machinery, presents the ZS-FAL32-10 Bottled Water Packaging Integrated Line. This turnkey solution streamlines your bottled water production, offering efficiency and quality.

Features and Components:

-

Water Treatment Unit:

- Removes impurities and ensures clean, safe water.

- Includes: Raw water tank, pump, filters, reverse osmosis system, UV sterilizer, finished water tank, and pump.

-

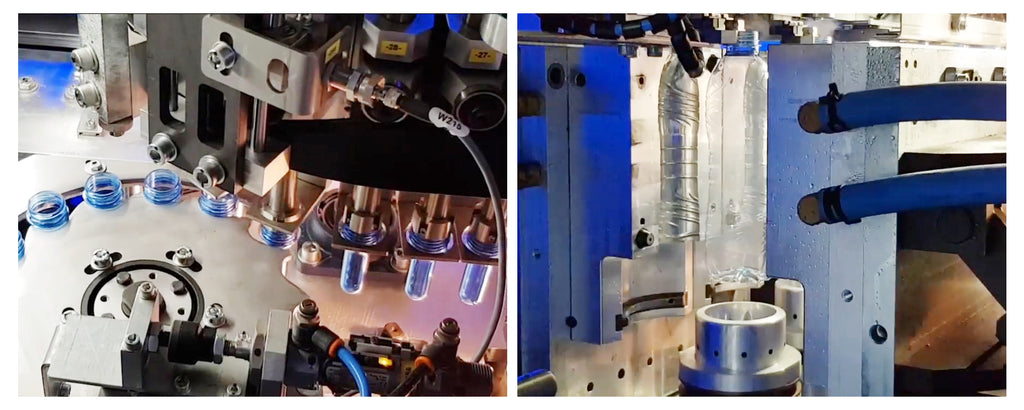

Blow-Molding Unit:

- Creates PET bottles in various sizes and shapes.

-

Rinse-Fill-Cap Unit:

- Cleans, fills, and caps bottles automatically.

-

Labeling Unit:

- Applies branding and information labels.

-

Shrink Wrapper Unit:

- Secures bottles for transport and distribution.

Advantages:

- Comprehensive Solution: Covers all aspects of bottled water production.

- Efficient Design: Minimizes customization needs and ensures quick startup.

- Easy to Use: Ideal for companies seeking efficient production.

- High-Quality Water: Guarantees clean and safe water for consumption.

Manufacturing Process:

- Water Treatment: Raw water undergoes filtration, reverse osmosis, and UV sterilization.

- Bottle Creation: Blow-molding unit shapes PET bottles.

- Filling and Capping: Rinse-fill-cap unit cleans, fills, and seals bottles.

- Labeling: Bottles receive branding and information labels.

- Wrapping: Shrink wrapper unit securely wraps bottles.

Customization Process:

- Bottle Size and Shape: Adjust blow-molding parameters.

- Material Compatibility: Customize components for different bottle materials (PET, glass).

- Label Design: Modify labeling unit settings.

- Production Speed: Adjust filling and capping speed.

ZONESUN's ZS-FAL32-10 Bottled Water Packaging Integrated Line offers a complete solution for high-quality bottled water production. Its efficiency, ease of use, and minimal customization make it an excellent choice for companies of all sizes. Rely on ZONESUN for your packaging needs!