Everything You Need to Know About Layered Filling Machines

Layered filling machines are a specialized type of packaging equipment designed to fill containers with multiple layers of liquids of different densities or colors. This technique is often used to create visually appealing products or to separate different ingredients, making it ideal for a wide range of applications in the food, beverage, cosmetic, and chemical industries.

Choosing the Right Layered Filling Machine: Key Considerations

Selecting the right layered filling machine for your specific needs requires careful consideration of several factors:

- Product characteristics: The type of product you are filling, its viscosity, and the desired number of layers will influence the choice of machine.

- Container size and shape: The size and shape of your containers will determine the compatibility with different filling systems and the overall efficiency of the process.

- Production volume: The volume of product you need to fill will dictate the capacity and speed of the machine required.

- Desired level of automation: The level of automation you desire will impact the complexity and cost of the machine.

- Budget: The overall budget you have allocated for the machine will influence the range of options available.

Zonesun: Your Trusted Partner in Packaging Solutions

At Zonesun, we are a leading manufacturer of packaging machinery with extensive experience in the field. We offer a wide range of high-quality and reliable layered filling machines to meet the diverse needs of our customers. Our team of experts is dedicated to providing comprehensive support and guidance throughout the selection and implementation process.

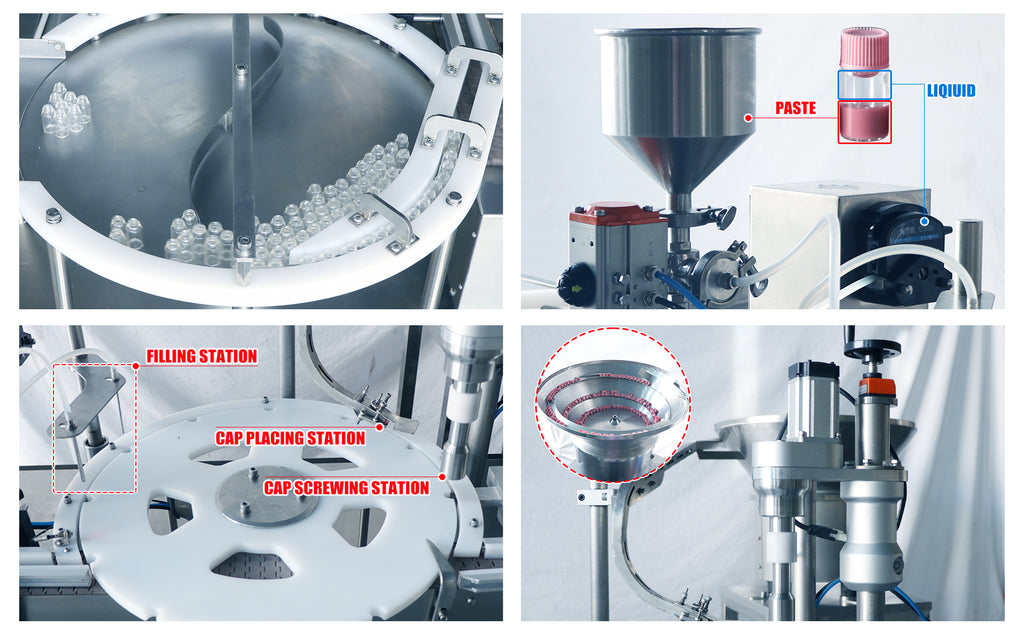

Introducing the ZS-AFC30: A Versatile Layered Filling Machine

The ZS-AFC30 is our flagship layered filling machine, designed to handle a wide variety of products and container types. This versatile machine features a dual-system design, allowing for seamless switching between paste and liquid filling, making it ideal for both food and cosmetic applications.

Key Features of the ZS-AFC30:

- Dual-system filling: Handles both paste and liquid products.

- Automatic capping: Applies caps securely and consistently.

- Torque adjustment: Ensures optimal cap tightness.

- User-friendly interface: Easy to operate and adjust settings.

- Compact design: Suitable for various production environments.

Benefits of the ZS-AFC30:

- Increased efficiency: Reduces manual labor and minimizes errors.

- Improved product quality: Ensures consistent filling and capping.

- Enhanced customer satisfaction: Delivers reliable packaging every time.

- Boosted productivity: Increases throughput and reduces downtime.

Contact Zonesun Today to Discuss Your Layered Filling Needs!

We invite you to contact Zonesun today to discuss your specific layered filling requirements. Our team of experts will be happy to answer your questions and provide you with a customized solution that meets your needs and budget.