ZONESUN

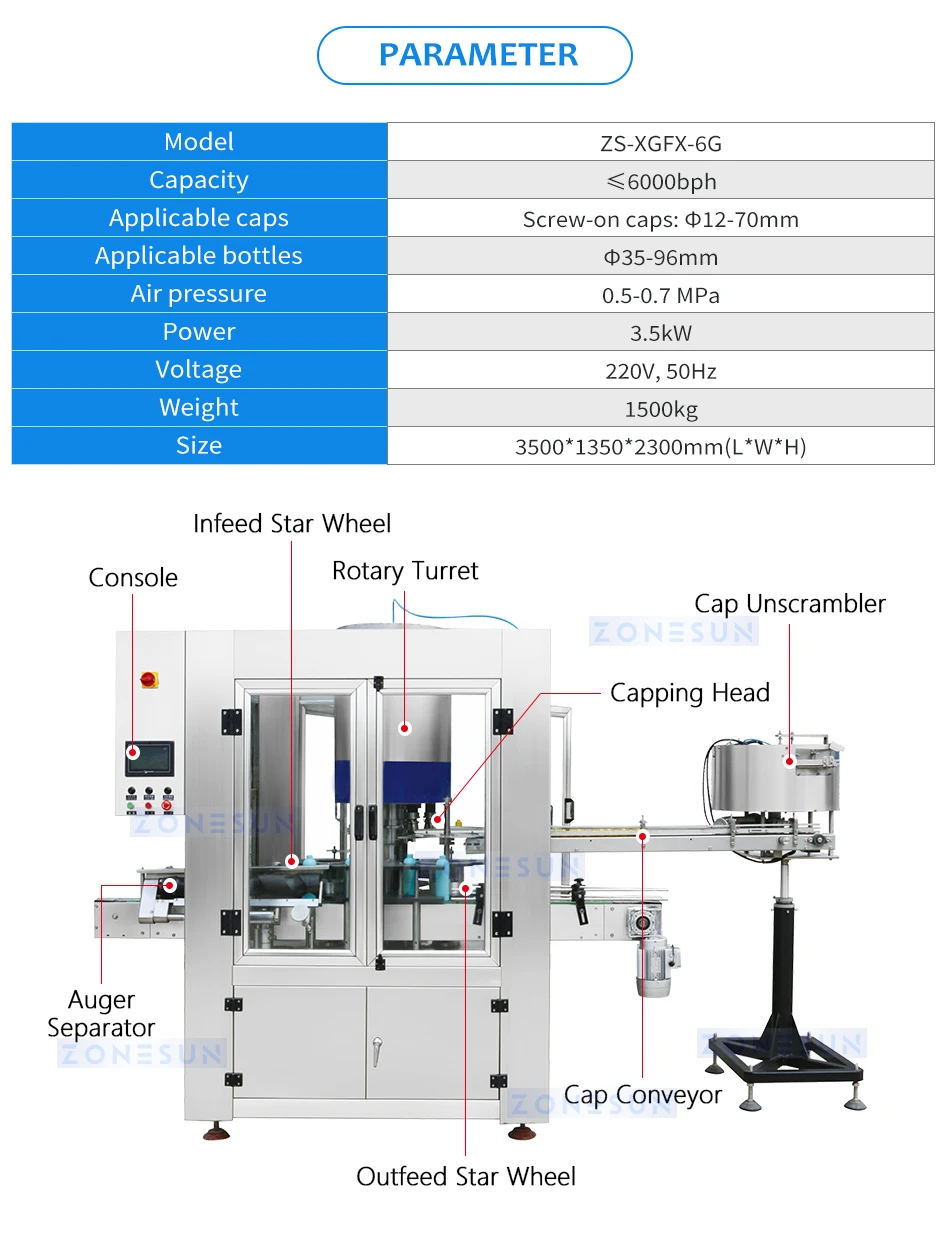

ZONESUN ZS-XGFX-6G Automatic High Speed Rotary Capping Machine

ZONESUN ZS-XGFX-6G Automatic High Speed Rotary Capping Machine

Verfügbarkeit für Abholungen konnte nicht geladen werden

DESCRIPTION

The Rotary Screw-on Capping Machine has a capacity to cap up to 6000 bottles per hour. The auger separator is responsible for separating the bottles and feeding them onto the infeed star wheel. The infeed star wheel moves the bottles in a single file towards the rotary turret. The rotary turret is the core of the machine, holding the bottles in place while the capping heads rotate to screw the caps onto the bottles. Once capped, the bottles move on to the outfeed star wheel, which moves them out of the machine for further processing. Above the outfeed star wheel, there is a star wheel for feeding caps transported from an outside cap unscrambler. Whatever your packaging needs are, you can rely on ZONSUN.

PARAMETER

|

Model |

ZS-XGFX-6G |

|

Capacity |

≤6000bph |

|

Applicable caps |

Screw-on caps: Φ12-70mm |

|

Applicable bottles |

Φ35-96mm |

|

Air pressure |

0.5-0.7 MPa |

|

Power |

3.5kW |

|

Voltage |

220V, 50Hz |

|

Weight |

1500kg |

|

Size |

3500*1350*2300mm(L*W*H) |

PRODUCT DETAILS

AUGER SEPARATOR

The auger separator is located at the beginning of the machine's production line and is responsible for separating the bottles from each other and feeding them onto the infeed star wheel. It consists of a motor-driven auger screw that rotates inside a tube.

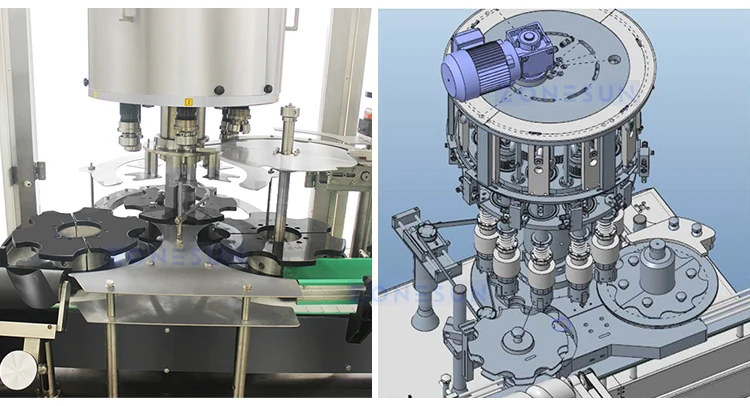

CAPPING

The rotary turret is the core of the machine and is responsible for holding the bottles in place while the capping heads screw the caps onto them. The capping heads are fitted with gripping mechanisms that hold onto the caps and rotate them as they screw onto the bottles. The turret is designed to move the bottles through the capping heads quickly and accurately, ensuring that each bottle is capped securely and with the same level of tightness.

CAP FEEDING

The cap unscrambler is responsible for sorting and orienting the caps and feeding them onto the cap conveyor. Once the caps are on the conveyor, they move towards the star wheel, which is designed to hold and support the caps in an upright position. The star wheel moves the caps towards the capping heads as they pass through the rotary turret.

COMPONENTS

It uses components from well-known brands, as these components are often reliable and of high quality. These components can help ensure that the machine operates smoothly and efficiently, with minimal downtime.